Your Source for Premium Automotive, Industrial and Marine Lubricants

Browse Our Catalog

99% Delivered On Time

& Environment Friendly

99% QC Passed

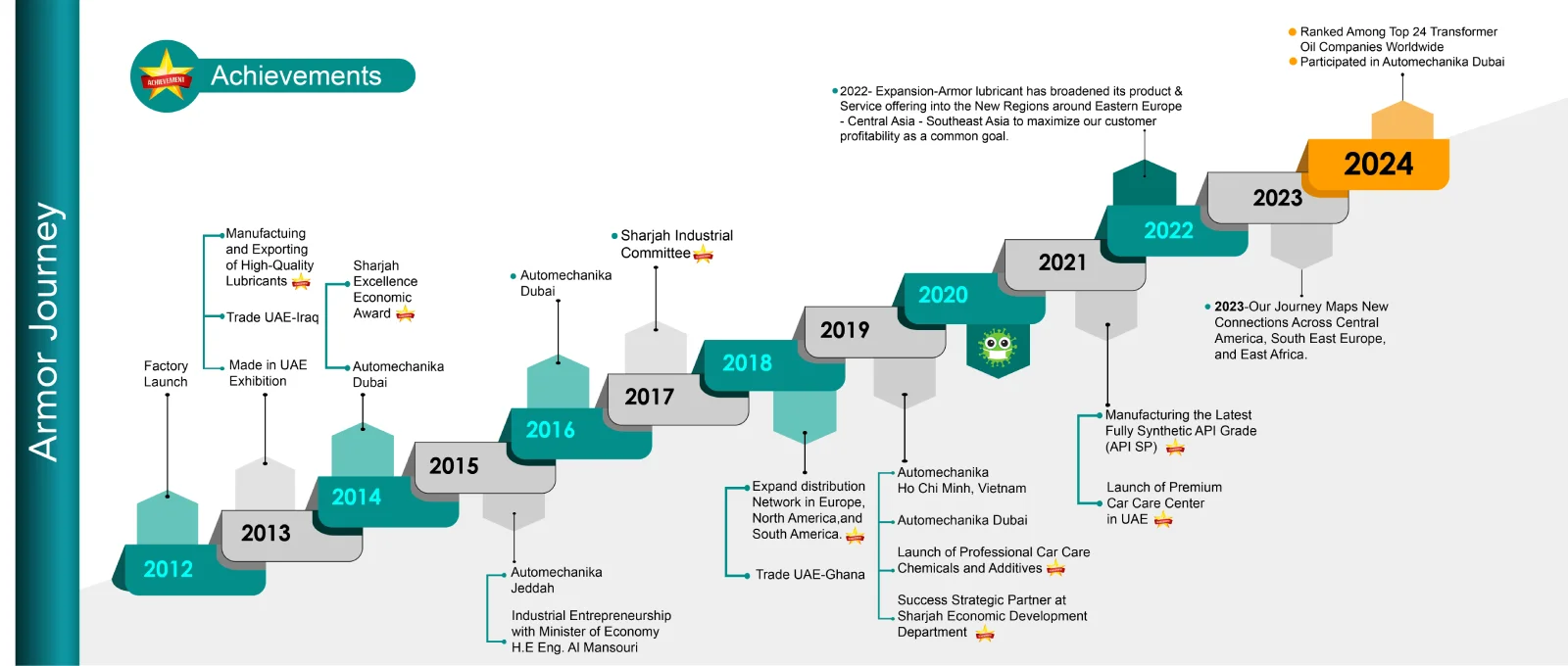

Welcome to Armor Lubricants, the leading lubricants Manufacturer in the UAE Since 2012! With a commitment to excellence and a wide range of high-quality lubricants, we are here to meet all your lubrication needs. Our team works hard to enhance the quality of our lubricants to deliver the best products that customers demand. Our mission statement and guiding principle have always been to meet the needs of our customers while maintaining a high level of product quality. To fulfill the needs of the industries and customers of lubricant oil, our direct sales business unit will try to produce products and services of the highest quality.

We're international company with a global footprint and local expertise. We ensure the same level of care and service for all our customers through our network.

We follow the highest ethics ond compliance standards. ISO quality, health, and safety management systems ensure compliance with international and national regulations. Our certifications provide our customers with additional assurances.

Having our own team of experts, we're always developing new tech. Our innovative and forward-looking solutions help shape the industry's future.

Our team is not only engineers, chemists, and manufacturers, but also racers and gearheads. As we work on our cars, tune them up, or cruise down the highway, we are at our best.

Armor Lubricants is one of the fastest-growing lubricants manufacturer in the UAE. Whether you operate in the automotive, industrial, marine, or agricultural sector, we have the expertise and high-quality lubricants products to ensure optimal performance and protection for your engine, machinery and equipment.

Discover More