- Armor Blog

- Industry

- The impact of Internet of Things (IOT) on the lubricants Oil and Gas industry

The Internet of Things, and How it will Change the Future of Lubricant Oil and Gas Industry

IoT is a term (Internet of Things) used to describe an ever-expanding network of internet-connected devices and systems that can communicate data in real time, without human involvement.

The Internet of Things (IoT) has been utilized in the lubricant company in UAE as the shape of sensors that track inventory levels, pump performance, and numerous functions that can be automated.

IoT aids to overcome some lapses that happen due to malfunction or miscalculation in data. Advancement in the IoT supports fixing many challenges in the oil and gas industry.

In this article, we will discover the challenges and more possibilities of IoT in this oil and gas industry, Examine IoT usage Case Study. Keep Reading to learn more!

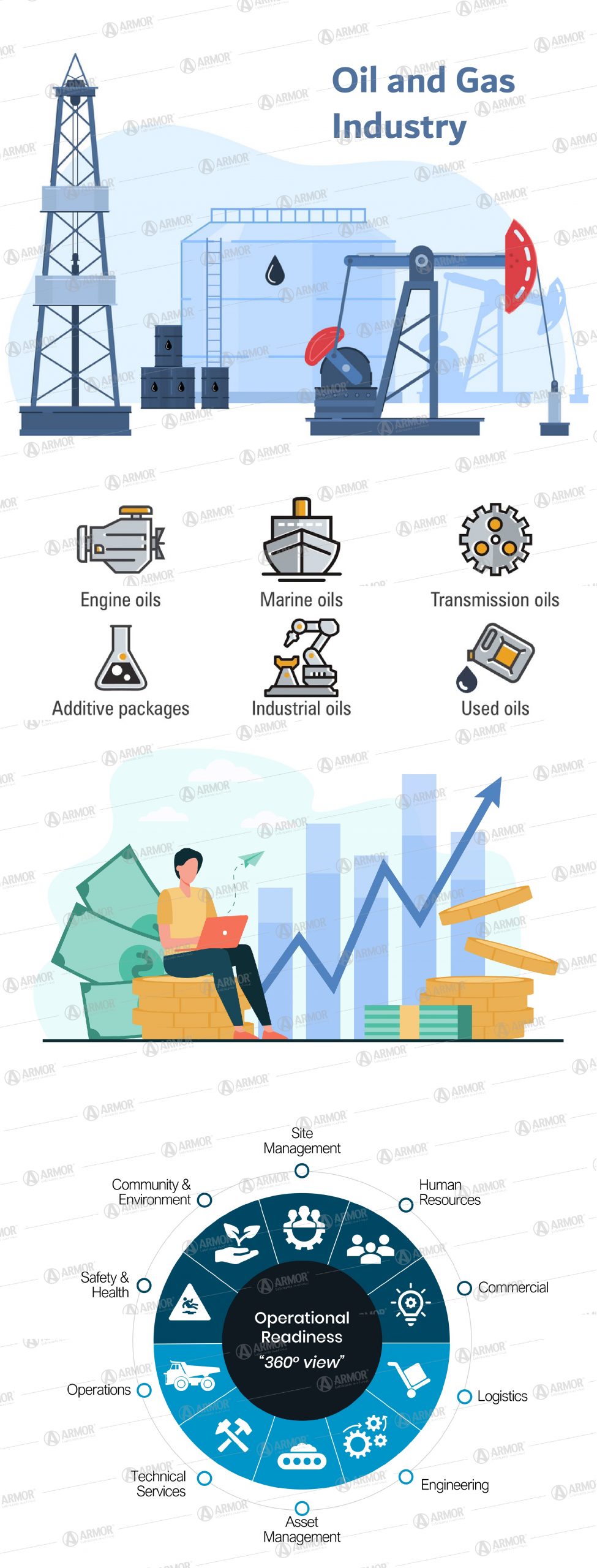

Barriers of Oil and Gas Industry

Reducing environmental impact to meet demanding standards:

Lubricant Oil Companies have been subjected to increasingly binding environmental standards. Therefore, companies like ARMOR LUBRICANTS have developed a smart Manufacturing and Distribution strategy to match the industry criteria.

Cost reduction to remain competitive:

It’s an ongoing challenge to produce crude oil & refined products at minimalist costs, so maintaining an optimized production and smart utilization on the existing Inservice sites using IoT will maximize Manufacturing efficiency the by decreasing the exploration costs.

Tired Machinery and outdated systems:

Heavy-Duty Machinery is used for Oil Extraction. Even today many wells rely on outdated processes and gear for calculations to preserve the performance & worker’s Safety. Advancing them will ease the process yet cost big money.

Opportunities for Oil & lubricants Industry:

IoT offers options to revolutionize the oil industry to enhance its performance.

Preventive Maintenance:

Data from Sensors, Artificial intelligence enables the detection of potential problems that lead and maintenance opportunities.

Drones and Robots:

Usage of progressive devices of IoT for oil industry plays crucial role in exploration, ongoing data gathering and 3D mapping

Safety:

Over time industry experts have developed Smart wearables to inspect the working conditions of workers performing dangerous tasks, and Algorithm for easy decision making.

The Internet of Things offers a potential economic impact of $4 trillion to $11 trillion a year in 2025.

-McKinsey

How Things Can Become More Efficient

Revenue Growth:

In the new-normal Lubricant oil companies in Dubai have learned to invest in innovative technologies rather than relying on the old downsizing techniques. Opting to industry-wide adoption of IoT could win economic stability, reduce costs and save time, increase the profit of the company.

Improved Operational readiness:

Implementing technology automation in oil companies decreases equipment malfunction and minimizes downtime.

Resourceful Decision-Making:

IoT integrations hands real-time data for making decisions about the next future steps in research, extraction, and distribution for the oil and gas Industry.

Scaled-down Safety Hazards:

A major concern for the oil and gas industry is safety, IoT adaptations benefit in recognizing the hazards remotely before they become actual problems.

Decreases Environmental Impact:

Introducing IoT aids the oil industry to control oil spills and using less energy promoting the positive environment.

IoT case study for oil Industry:

Oil major Shell is using Internet of Things (IoT) connectivity solutions to enhance its oversight capabilities in its operations in Nigeria.

In addition, many of Shell’s wells are located in difficult areas, confined thousands of meters below ground. To make maneuvers more efficient, Shell turned to smart field technology. We have installed thousands of sensors in devices such as valves and pumps. Sensors collect data on temperature, pressure, and other measurements and send them to a control center on land. Here, engineers read measurements and monitor production in real time to optimize individual processes.

Contact Armor Lubricants and learn about Lubricants we offer. Armor Lubricant has a rich portfolio and solid experience in the Manufacture and distribution of oil products and is available to. Just drop us a text and tell us about your needs.

Spear Lubricants

Spear Lubricants Armada lubricant

Armada lubricant Ace lubricants

Ace lubricants Perfect lubricants

Perfect lubricants Enzo lubricants

Enzo lubricants Lawrence lubricants

Lawrence lubricants