- Armor Blog

- Products

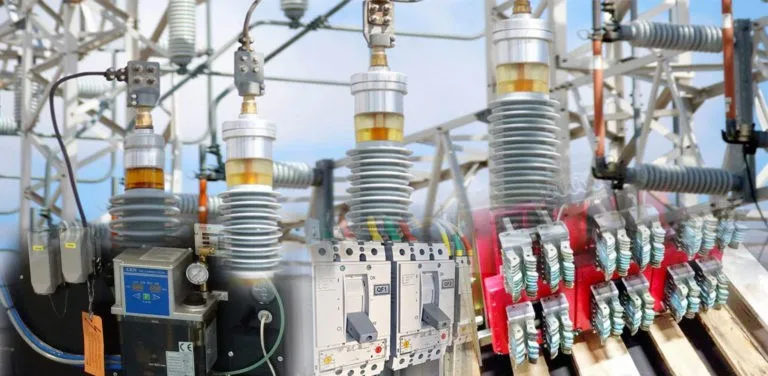

- Dielectric Transformer Oil: Everything You Need to Know

Dielectric Transformer Oil Properties & Benefits

Dielectric transformer oil is a critical component of transformers, as it helps to insulate the windings and prevent electrical breakdown. In this blog post, we’ll take a closer look at dielectric transformer oil, including its properties, benefits, and how to choose the right one for your transformer.

Dielectric transformer oil is a type of oil that has excellent insulating properties. It is also non-conductive, which means that it does not conduct electricity. This makes it ideal for use in transformers, as it helps to prevent electrical breakdown and keep the windings from shorting out.

Types of Insulating Oil

Like some other types of oil, such as motor oil, insulating oil’s purpose can be found in its name. This type of industrial oil is designed for use in power transformers, which play a critical role in the energy grid. It is also called insulating oil for this reason.

What Does It Do?

Unlike other oils, transformer insulating oil is not designed to reduce friction. However, it is designed to help reduce temperature – motor oil does this to an extent, as well. With that being said, this oil also has a second, even more important, task. That is, it is designed to insulate it. Because of this, the oil differs greatly from other types of lubricants in terms of properties. In order to be used within a transformer, an oil must:

- Have a high dielectric strength

- Have high thermal conductivity

- Have high chemical stability

- Must be able to maintain all characteristics at very high temperatures and for long periods of time

This dielectric transformer oil is used to preserve the windings and core within a power transformer. Without this dielectric oil, transformers would quickly overheat and suffer damage from corona discharge, arcing, and more.

Types of Dielectric Transformer Oil

Most dielectric transformer oil are mineral based. The two most common options on the market are paraffin-based oil and naphtha-based oil. Of these, naphtha oil oxidizes more easily, but the sludge produced during oxidation is more soluble than what is produced within paraffin-based oil. This means that the sludge does not collect at the bottom of the transformer where it would eventually obstruct convection circulation within the oil.

Paraffin-based transformer oil does not offer the same benefit and sludge can more easily collect at the bottom of the transformer. It also has a high pour point, which can be an issue in colder climates.

Some of the benefits of using dielectric transformer oil includes:

- Excellent insulating properties

- Non-conductive

- High flash point

- Low pour point

- Resistant to oxidation and corrosion

Other Applications

Transformer insulating oil is primarily used in the world of power generation. However, it does have uses in other situations. It can be used in any situation in which insulation is necessary within an electrical component, and is well-suited to very high-voltage applications. For example, high-voltage switches and capacitors, as well as some types of circuit breakers can benefit from the cooling and insulating properties of this oil.

Regular Testing

Finally, because transformer oil is a safety precaution, it must be tested regularly and replaced when its properties have been altered. On-site inspections should be conducted twice per year, and samples should be tested for dissolved gasses annually. If a transformer has been in operation for five years, this dielectric transformer oil should be subject to Furan testing every two years.

In conclusion,

choosing the right transformer oil is crucial for maintaining the efficiency and longevity of electrical transformers. Armor Lubricants offers high-performance transformer oils that provide excellent insulation, high safety, cooling, and protection for industrial transformers. If you’re looking for a reliable transformer oils which meets industry standards, the explore our transformer oil products to find the best industrial solution and ensure the electrical systems operate at peak performance. Trust Armor Lubricants industrial oil for quality and reliability.

Spear Lubricants

Spear Lubricants Armada lubricant

Armada lubricant Ace lubricants

Ace lubricants Perfect lubricants

Perfect lubricants Enzo lubricants

Enzo lubricants Lawrence lubricants

Lawrence lubricants