- Armor Blog

- Technical

- Understanding Lubricant Viscosity: The Key to Optimal Lubrication

Understanding Viscosity of Lubricant

Viscosity of lubricant is an important property as viscosity gets directly affected by the temperature. Lubricating fluids are designed with the aim of overcoming the shortcomings of mineral or conventional oil. The primary idea of using the lubricant is to reduce the friction between the vehicles.

A Right viscosity of lubricant for your application is an important property as viscosity gets directly affected by the temperature. The formulation and quality of the lubricant determine the drop level of the viscosity with the increase in temperature. For accurate and proper lubrication, the viscosity will depend on the bearing conditions which include the operating temperature, speed, load, bearing design, and other application methods.

Why it is important to select the right Viscosity of lubricant?

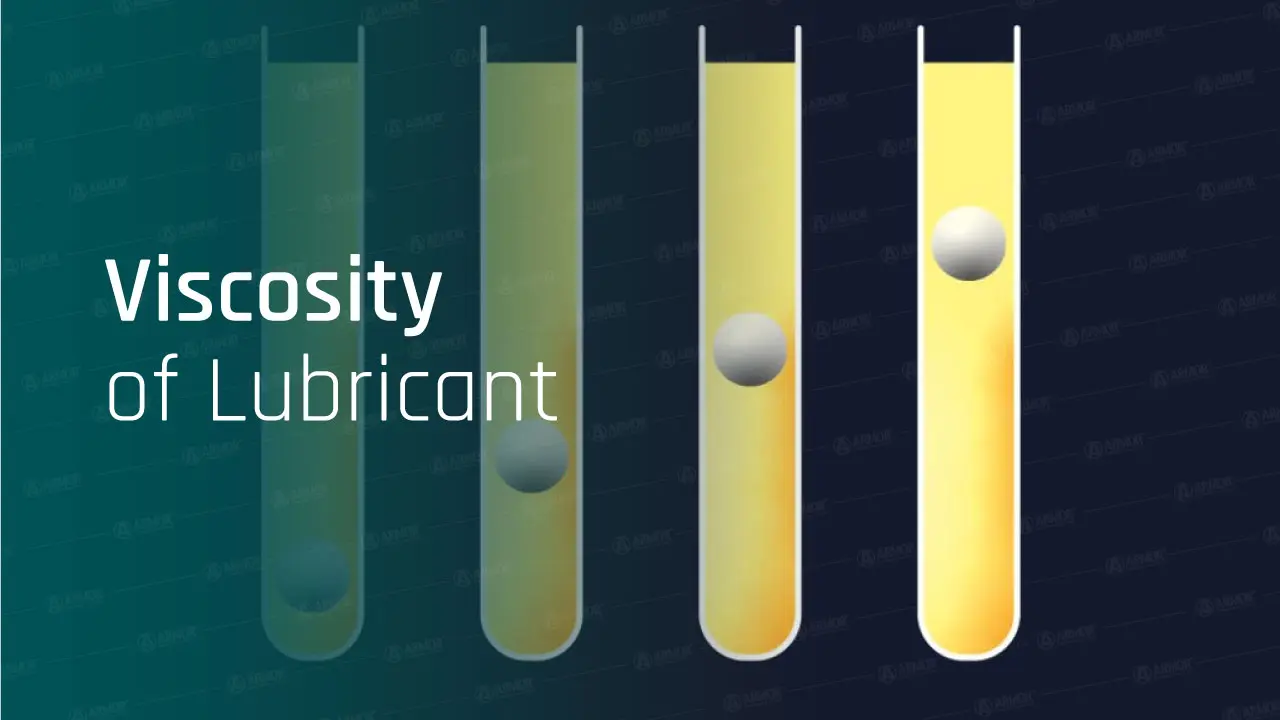

The viscosity of lubricant is its resistance to flow. It is a measure of how thick or thin a liquid is. In lubricants, viscosity is important because it affects the ability of the lubricant to protect and lubricate moving parts. A lubricant with too low a viscosity will not be able to provide adequate lubrication, while a lubricant with too high a viscosity will not be able to flow freely and may cause overheating.

The right viscosity of lubricant for a particular application will depend on a number of factors, including the type of machine, the operating conditions, and the ambient temperature. For example, a lubricant with a high viscosity may be required for a machine that operates in cold temperatures, while a lubricant with a lower viscosity may be required for a machine that operates in hot temperatures.

Here are some of the reasons why it is important to select the right viscosity of lubricant:

- To protect moving parts Lubricants help to protect moving parts by forming a film between the parts. This film helps to prevent the parts from rubbing against each other, which can cause friction and wear. The viscosity of the lubricant affects the thickness of the film, and a lubricant with the wrong viscosity may not be able to form a thick enough film to protect the parts.

- To lubricate moving parts Lubricants also help to lubricate moving parts by reducing friction. Friction can cause heat, which can damage the parts. The viscosity of the lubricant affects the ability of the lubricant to reduce friction, and a lubricant with the wrong viscosity may not be able to reduce friction enough to protect the parts.

- To prevent overheating Lubricants help to prevent overheating by carrying away heat from the moving parts. The viscosity of the lubricant affects the ability of the lubricant to carry away heat, and a lubricant with the wrong viscosity may not be able to carry away enough heat to prevent overheating.

If the wrong lubricant viscosity is used, it can lead to a number of problems, including:

- Increased wear and tear on moving parts This can lead to premature failure of the parts.

- Overheating This can damage the parts and shorten their lifespan.

- Loss of efficiency The machine may not be able to operate at its full capacity.

- Increased noise The machine may operate louder than normal.

Therefore, it is important to select the right lubricant viscosity for a particular application in order to protect the moving parts, prevent overheating, and maintain the machine’s efficiency.

Here are some tips on how to select the right lubricant viscosity:

- Consult the manufacturer’s recommendations: The manufacturer of your machine will usually have recommendations for the correct lubricant viscosity.

- Consider the operating conditions: The operating conditions of your machine, such as the ambient temperature and the type of load, will also affect the correct viscosity of lubricant.

- Use a viscosity chart: A viscosity chart can help you to determine the correct lubricant viscosity for your application.

- Change the lubricant viscosity as needed: The viscosity of lubricant can change over time, so it is important to check the viscosity periodically and change the lubricant if necessary.

Pre-planning is the best way to deal with Environmental Changes

Grease can enhance performance as it is made up of oil base stock, thickeners, and functional extracts. You should keep in mind the application environment at the time of selecting the appropriate industrial lubricants.

Making a selection of the lubricant for your application is not an easy task. It requires years of experience and with this, the environment also plays an aggressive role. The sudden change in the environment such as high or low moisture, corrosion, and other external temperatures may bring an adverse effect on the lubricant. Sometimes it becomes difficult to judge at which temperature the lubricant will get complete support and at which temperature the lubricant will not get the support. So, to remove this hurdle one should have knowledge about the lubricant and its types.

What is the role of Lubricants?

The primary idea of using the lubricant is to reduce the friction between the vehicles. The lubricant oil are designed with the aim of overcoming the shortcomings of conventional or mineral oil. To make your doubts clear we are here with the advantages of Lubricant Oil. So, let’s have a look at the points and clear up our doubts.

The advantages of Lubricant Oil are as follows-

- It can increase energy efficiency

- It can extend the oil change intervals.

Lubricant manufacturers produce paper machine oils so as to fulfill the requirements of different types of machines. So, it becomes necessary that you should have complete knowledge of the type of lubricant you are using for your application.

In order to select the right industrial lubricant, one should consider several factors as the lubricant plays a vital role in completing the work and getting all the tasks done on time. To give the direction to your thoughts the customer should understand the 4 C’s to Lubrication:

- Correct Technology

- Correct Quantity

- Correct Frequency

- Correct Procedures.

These 4 ‘Cs’ will make your task easy as it will determine the type of lubricants that will be best for your application and you should also understand the present situation i.e. environmental changes will also leave a direct effect on the usage of the lubricant.

- The temperature of the place will determine the type of lubricant oil one should use

- Speed determines the requirement of viscosity

- Load, vibration, and moisture will decide the packaging of the products.

Final Words

We are all familiar with the fact that great deals of technological advancement are taking place and tons of new products are seen on the market. The increasing demand for steel, cement, automotive, and other agricultural products is automatically giving the hype to the market for lubricants and it is giving rise to the usage of the right viscosity of lubricant.

Spear Lubricants

Spear Lubricants Armada lubricant

Armada lubricant Ace lubricants

Ace lubricants Perfect lubricants

Perfect lubricants Enzo lubricants

Enzo lubricants Lawrence lubricants

Lawrence lubricants