- Armor Blog

- Technical

- Lubricant Reception and Storage Process

Lubricant Reception and Storage: We Expect You to Have This Knowledge Explained

Armor Lubricants takes care of the lubricants we deliver to companies and we strive to make clean high-quality lubricants. Before blending the raw materials with the machine parts, Armor Lubricants visually inspects them. In the manufacturing process of lubricants, impurities can occur at any stage. Hence, you should be careful when choosing lubricant oil for your machine.

Lubricant Reception and Storage is the critical part and if it is stored carefully then it completes the lubricant life cycle. Be careful while storing and handling the lubricants because one missed step may disturb the lubricant life cycle and it may end in loss. The essential task of an organization is storing the lubricant properly. A machine is an Asset and ensuring that it is receiving the best lubricant should be the priority of the machine owners.

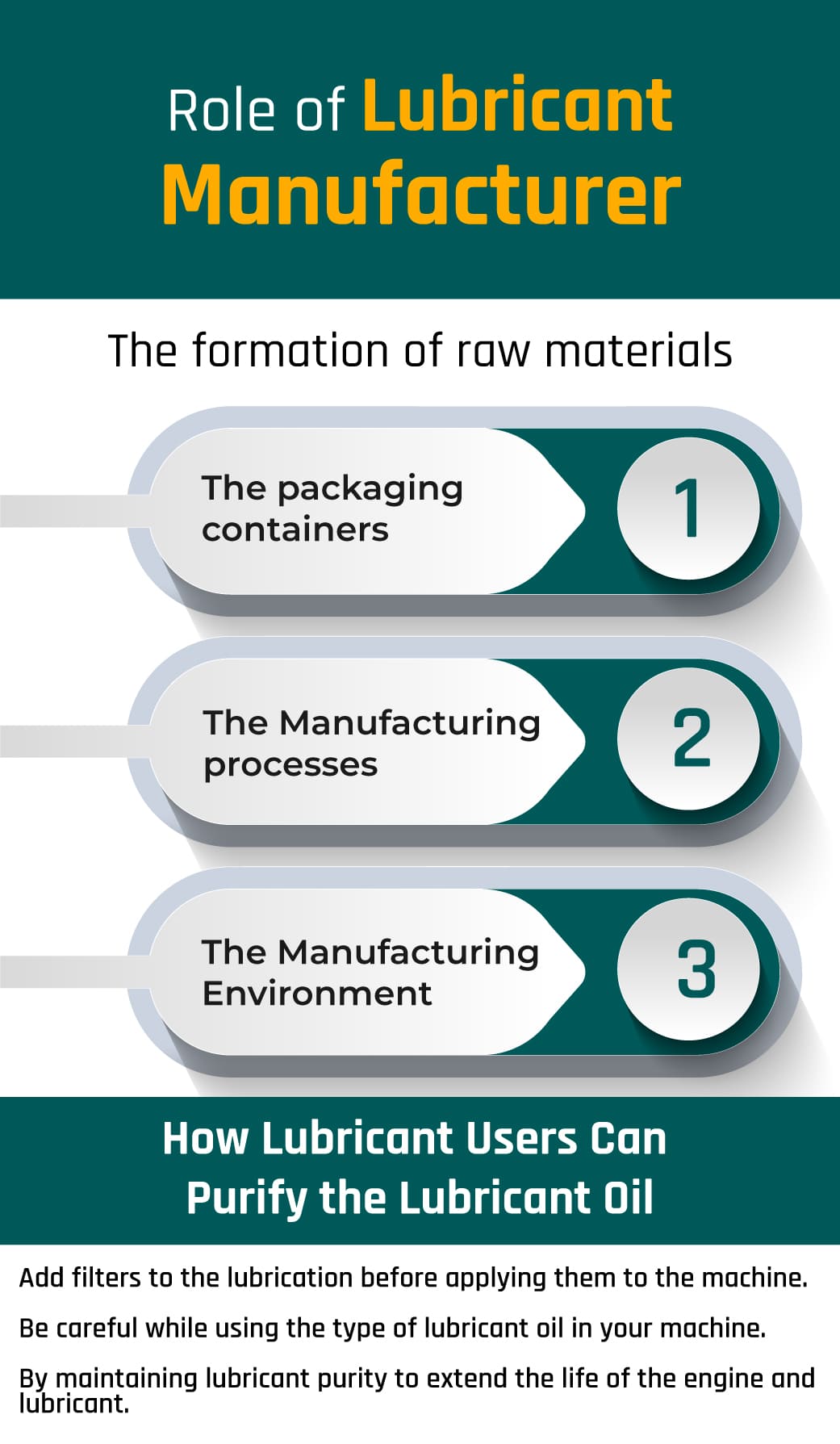

What is the Role of Lubricant Manufacturer?

Leading Lubricant manufacturer takes care of the products we deliver to the companies as our vision is to produce high-quality lubricant products. But still, it includes wreckages, corrosion, oxidation, and chips from oil drum liners. To give you a clear picture that from where the lubricant gets dirty then here are some culprits that are responsible for contaminating the manufacturing process are as follows-

- The formation of raw materials

- The packaging containers

- The manufacturing processes

- The manufacturing environment

We, Armor Lubricants visually inspect the raw materials before delivering and blending them with the parts of the machine. The materials are loaded into blending kettles, screens are used to catch the unwanted materials. The manufacturer uses filters for large-sized particles and these screens will help to control contamination. It identifies the size of the filters it is using for the purpose of filtering.

How Lubricant Users Can Purify the Lubricant Oil?

Impurities can take place at any step of the lubricant manufacturing process. It can take place at any step from mixing the base oils and additives down to tank storage and distribution.

You can add filters to the lubrication before applying them to the machine. This process will solve half of your work and you will be able to serve the pure lubricant to your machine. By simply keeping the target of cleanliness at the time of receiving or delivering the lubricant you will not only enhance the life of the machine but you will also extend the life cycle of the lubricant.

The lubricant should meet the complete procedure of cleanliness before it reaches its destination. You should be careful at the time of lubricant reception and storage. There are chances that you can receive or deliver the dirty lubricant if you have no control over the place of the lubricant.

For example, if the lubricant is to be delivered to a site without going through the procedure of cleanliness, then it will directly harm the parts of the machine and sometimes the dirty lubricant will destroy the machine which ends up in the loss of the company.

If you want that machine should give you its complete support then you should ensure the quality of the lubricant is high and most importantly it should not contain any type of impurities, contaminate objects, or foreign bodies. The main reason for machine failure and severe changes are the impurities added to the lubricant oil. So, it is necessary that you should be careful while using the type of lubricant oil in your machine.

Closing Lines

You know that the companies are collaborating with established and trustworthy lubricant companies like Armor Lubricants because they know that the life of the machine totally depends on the type and quality of the lubricant it is using.

Certified protection and performance are provided by Armor Lubricants. For automotive, industrial, and marine applications, we offer professional-grade lubricants, chemicals, and other products.

If you’re looking for more information about Armor lubricants, reach out to us.

Spear Lubricants

Spear Lubricants Armada lubricant

Armada lubricant Ace lubricants

Ace lubricants Perfect lubricants

Perfect lubricants Enzo lubricants

Enzo lubricants Lawrence lubricants

Lawrence lubricants