- Armor Blog

- Consumer Education

- How To Choose The Most Suitable Hydraulic Oil for Machinery?

How do you ensure that you choose the right type of hydraulic oil for your equipment?

Hydraulic systems play vital roles in a wide range of industries. They’re used in mechanic shops to power vehicle lifts. They’re found in booms on construction equipment. Really, hydraulic systems are everywhere, and they all require the right type of hydraulic oil. How do you ensure that you choose the most suitable options for your equipment?

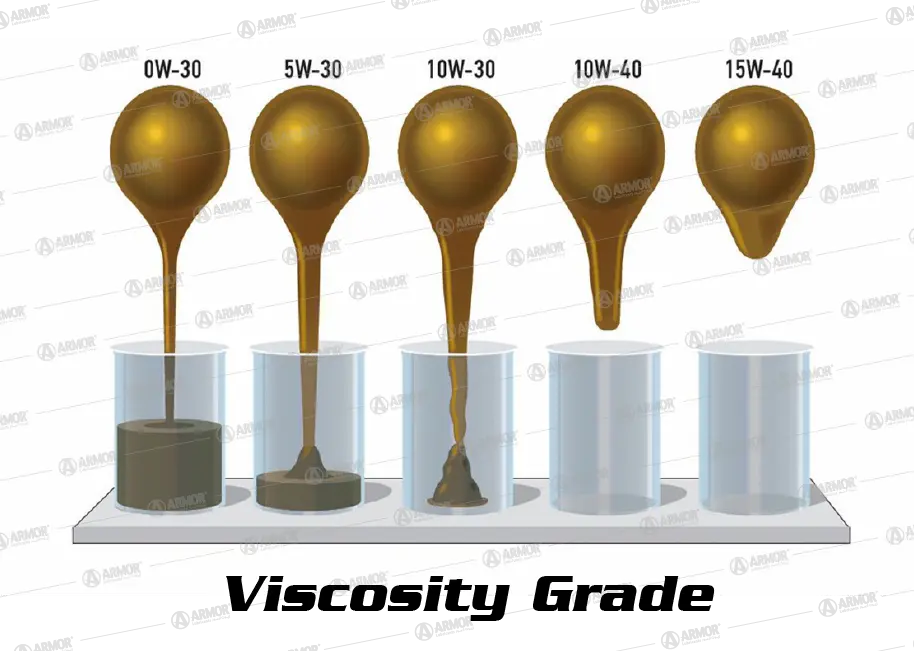

Viscosity

One of the first considerations here is going to be viscosity, or thickness/fluidity. If the hydraulic oil is too heavy for your system, it will not offer the right performance. If the hydraulic oil is too thin/lightweight, it will not provide the protection that you need. Viscosity of lubricants plays a role in everything from volumetric efficiency to mechanical efficiency, heat dissipation, air release, cavitation, and more.

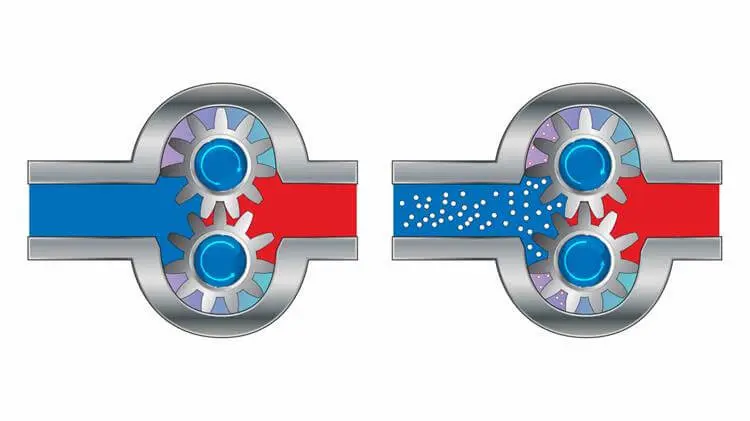

Hydraulic Oil and Anti-Wear (AW) Protection

Any type of hydraulic oil (aw 37, aw 46, aw 68) you choose should have the right anti-wear (aw) properties to help ensure a longer use life for your equipment. This is achieved with additives within the oil that form a protective film over surfaces in order to prevent friction from metal-on-metal contact.

Easily Filtered

All hydraulic oil will pick up particles – metal shavings from internal components, contaminants from buildup within the system, and more. These particles must be cleaned from the fluid to prevent damage, which happens as the fluid passes through a filter. If the fluid is not easily filterable, it may cause blockage within the system.

Corrosion Protection

Your hydraulic fluid should offer good protection from both rust and acidic chemical corrosion. These are caused by water penetration into the system. Ferrous metals within the system will begin to rust without corrosion protections, and acidic corrosion can attack other elements in the system

Seal Compatibility

All hydraulic systems have seals that allow them to operate. Usually, these seals are made from softer material, such as rubber. However, not all hydraulic oils are compatible with all types of seal materials, so it is important to make sure that the hydraulic oil you ultimately choose is rated as safe for the seals in your system.

Additional Information:

Know Which Industries Most Use Hydraulics And How Do They Benefit.

Thermal Stability

Many lubricants thin out when they heat up. You cannot afford for this to happen with your hydraulic oil (aw 37, aw 46, aw 68), as it can cause damage from heat, friction, and more. This leads to premature wear and tear, and eventually to failure.

Oxidation Stability

When hydraulic fluid is exposed to oxygen, oxidation can take place. This can form an acidic by-product within the fluid that etches metal components and damages your equipment. Note that oxidation can be exacerbated by high temperatures, so good oxidation stability and thermal stability are both required.

Disposal

Eventually, you will need to drain and replace your hydraulic oil, which also means you will need to dispose of the old fluid. This can be problematic. Toxic hydraulic fluids can be costly or even impossible to dispose of properly depending on the facilities within your area.

In Conclusion

Armor Lubricants and Hydraulic Oil

Armor Lubricants, a leading manufacturer of hydraulic oil in UAE, understands these complexities and offers a comprehensive range of high-quality hydraulic oils engineered for various applications and operating conditions. When you choose Armor Lubricants, you’re choosing reliability, performance, and the expertise of a trusted manufacturer.

Armor Lubricants is an Emirati establishment who manufactures industrial lubricants and specially premium quality hydraulic oil using advanced German technology. The factory is approved by the API and is certified for ISO 9001, ISO 14001, and ISO 45001 for Management, Quality, and Occupational Health and Safety. Exports lubricants to Worldwide.

Spear Lubricants

Spear Lubricants Armada lubricant

Armada lubricant Ace lubricants

Ace lubricants Perfect lubricants

Perfect lubricants Enzo lubricants

Enzo lubricants Lawrence lubricants

Lawrence lubricants