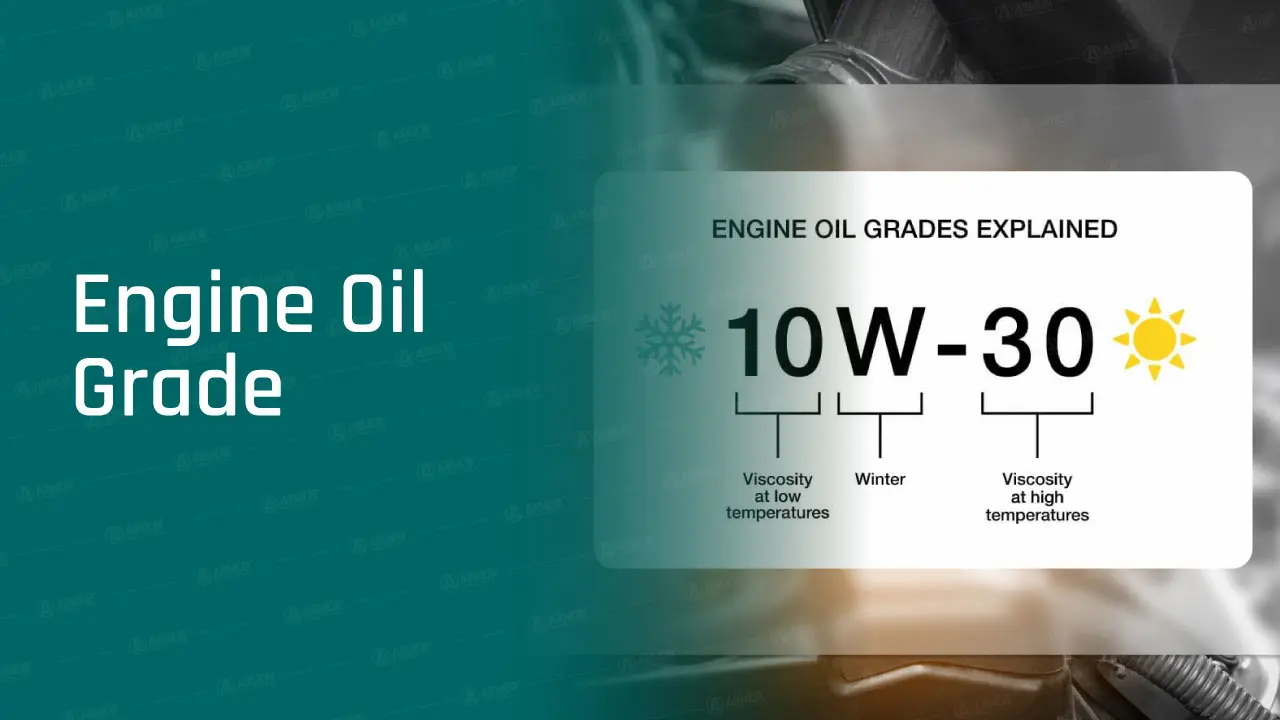

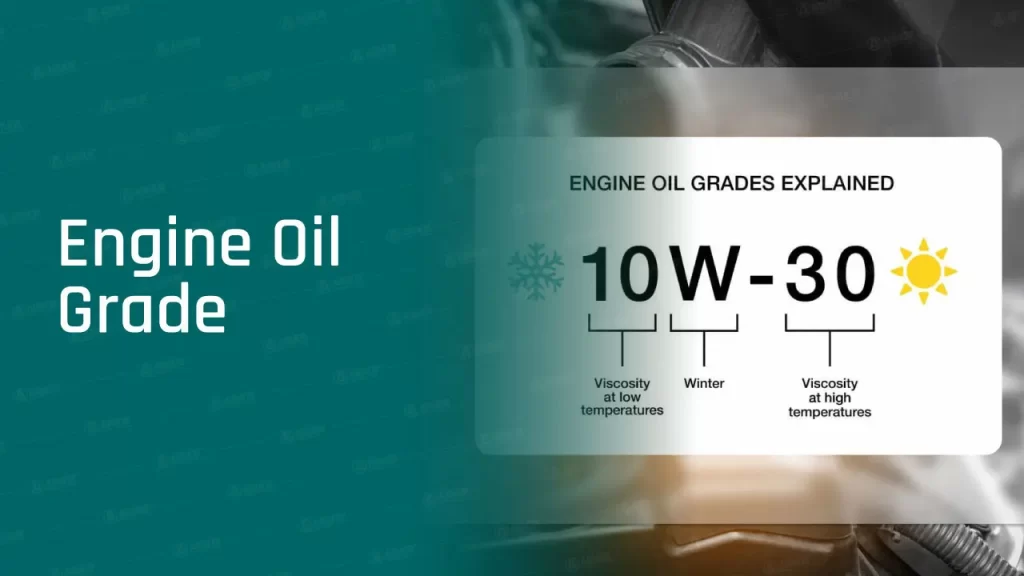

Why do not we make one motor oil for both diesel and petrol engines? Because they are different from each other. 5W30 engine oil for diesel engines do not have same components as 5W30 for petrol even if they share the base oil.

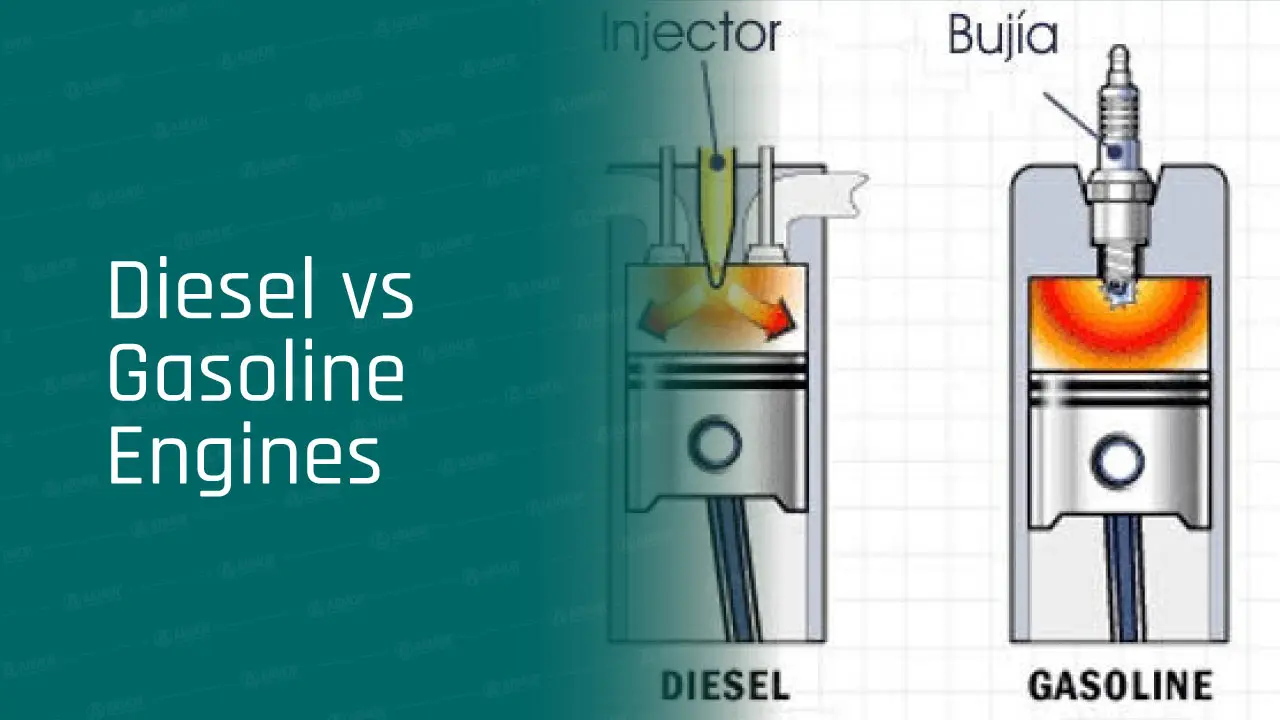

What are the fundamental differences between diesel and gasoline engines?

Diesel and gasoline engines operate on internal combustion principles, but their components, fuel injection, lubrication, cooling, and exhaust systems differ significantly. These differences impact performance, fuel efficiency, and maintenance requirements.

Components of Internal Combustion Engines

Both engine types consist of pistons, cylinders, crankshafts, and valves, but their design varies based on combustion pressure and fuel type.

- Diesel Engines – Built with stronger, heavier components to withstand higher compression ratios (typically 14:1 to 25:1). They also feature glow plugs for cold starts.

- Gasoline Engines – Have lighter components designed for lower compression ratios (8:1 to 12:1), relying on spark plugs for ignition.

Injection System

Fuel injection is one of the key differences between diesel and gasoline engines, affecting efficiency and combustion characteristics.

- Diesel Engines – Use direct fuel injection at high pressure, ensuring better fuel atomization and higher efficiency.

- Gasoline Engines – Typically use port fuel injection (PFI) or direct injection (GDI), requiring precise air-fuel mixture control for smooth performance.

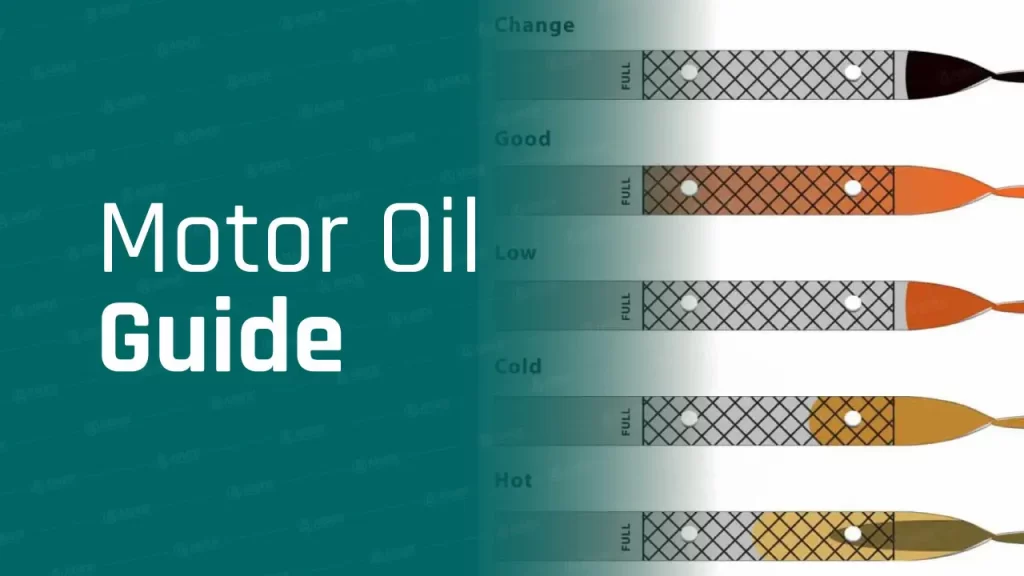

Lubrication System

Lubrication is critical for engine longevity, but diesel and gasoline engines require different oil formulations.

- Diesel Engines: Require thicker, high-detergent oils to handle soot and combustion byproducts. Lubrication must support higher loads and extreme pressures.

- Gasoline Engines: Use lighter, lower-detergent oils that optimize fuel efficiency and catalytic converter longevity.

Cooling System

The cooling requirements differ due to combustion temperatures and engine loads.

- Diesel Engines: Generate more heat due to high compression, requiring larger radiators and heavy-duty cooling systems.

- Gasoline Engines: Run at lower combustion temperatures, needing smaller cooling systems.

Exhaust System

Emission control technologies vary between the two engine types.

- Diesel Engines: Equipped with Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) to reduce soot and nitrogen oxides.

- Gasoline Engines: Use Three-Way Catalytic Converters (TWC) to manage carbon monoxide, hydrocarbons, and nitrogen oxides.

How do diesel and petrol engines ignite fuel?

Diesel and gasoline engines use different ignition methods due to their distinct combustion processes and fuel properties.

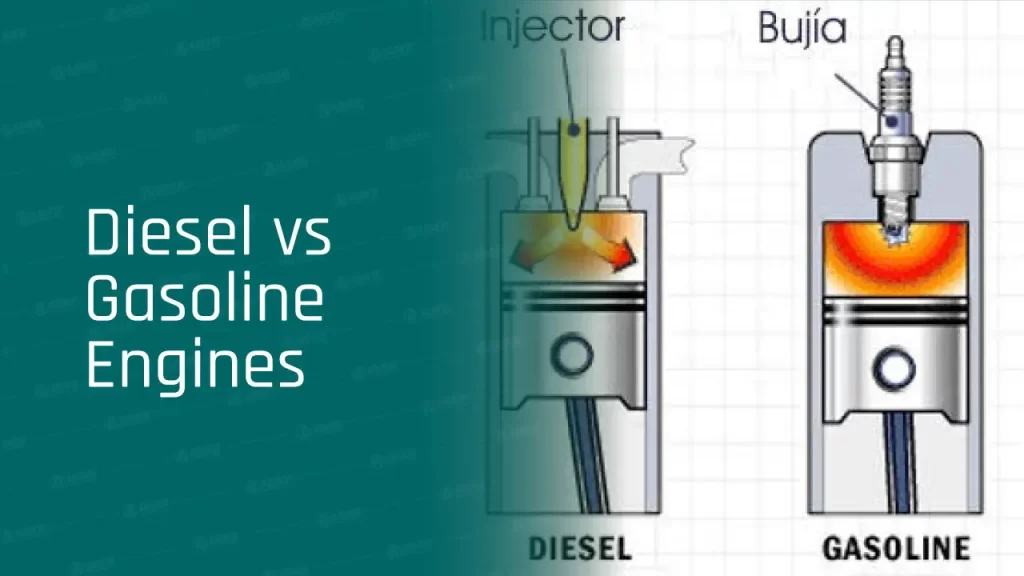

Diesel Engines – Rely on compression ignition (CI). The air is highly compressed inside the cylinder, raising its temperature. Fuel is then injected directly into the hot, pressurized air, igniting spontaneously without a spark.

Gasoline Engines – Use spark ignition (SI). A mixture of air and fuel is compressed, and a spark plug ignites the mixture at the right moment, creating controlled combustion.

What’s the difference in compression ratios?

The compression ratio refers to how much the air-fuel mixture is compressed before ignition. Diesel engines have significantly higher compression ratios than gasoline engines.

Diesel Engines – Typically have a compression ratio between 14:1 and 25:1. Higher compression increases thermal efficiency, making diesel engines more fuel-efficient.

Gasoline Engines – Operate with a compression ratio between 8:1 and 12:1. Lower compression prevents premature detonation (knocking) and supports smoother combustion with a spark plug.

How does fuel efficiency compare between diesel and gasoline engines?

Fuel efficiency differs significantly between diesel and gasoline engines due to their combustion processes, energy density, and thermal efficiency. Diesel engines generally consume less fuel while delivering higher mileage, making them the preferred choice for heavy-duty applications and long-distance travel.

Why Are Diesel Engines More Fuel-Efficient?

- Higher Compression Ratios

- Diesel engines have compression ratios between 14:1 and 25:1, compared to 8:1 to 12:1 in gasoline engines.

- Higher compression increases thermal efficiency, allowing diesel engines to extract more energy from each drop of fuel.

- Energy Density of Diesel Fuel

- Diesel fuel contains more energy per liter than gasoline.

- This results in better fuel economy, especially for vehicles covering long distances.

- Leaner Air-Fuel Mixtures

- Diesel engines operate with a leaner air-fuel mixture, meaning they use less fuel per unit of air than gasoline engines.

- This helps improve fuel efficiency and reduces fuel consumption under low loads.

- Lower Engine Speed (RPM)

- Diesel engines run at lower RPMs, reducing fuel consumption.

- Gasoline engines operate at higher RPMs, consuming more fuel to maintain power output.

Fuel Consumption Comparison

- Diesel Engines: Typically provide 20-30% better fuel economy than gasoline engines of similar size and power.

- Gasoline Engines: Burn fuel more quickly due to their lower compression ratios and higher RPM operation.

What’s the impact on long-term fuel costs?

Long-term fuel costs depend on fuel efficiency, fuel prices, and maintenance expenses. Diesel engines typically have lower fuel consumption, leading to cost savings over time, but factors like fuel prices, initial costs, and maintenance influence overall expenses.

Why Diesel Engines Reduce Long-Term Fuel Costs

- Better Fuel Economy

- Diesel engines consume 20-30% less fuel than gasoline engines for the same distance traveled.

- Lower fuel consumption means fewer refueling stops and reduced spending over time.

- Higher Energy Density of Diesel Fuel

- Diesel contains more energy per liter, delivering better mileage compared to gasoline.

- This is especially beneficial for long-distance driving and commercial vehicles.

- Lower RPM Operation

- Diesel engines run at lower RPMs, reducing fuel burn.

- Less strain on the engine helps maintain fuel efficiency over the vehicle’s lifespan.

How do emissions and environmental impact differ between diesel and gasoline engines?

Diesel and gasoline engines differ significantly in their emissions and overall environmental impact. While diesel engines are more fuel-efficient and produce less CO₂ per kilometer, they generate higher nitrogen oxides (NOx) and particulate matter (PM). Gasoline engines, on the other hand, emit more CO₂ but lower levels of harmful pollutants, making them cleaner in certain conditions.

Differences in CO₂ Emissions

Carbon dioxide (CO₂) emissions are directly related to fuel consumption. Diesel engines are more efficient than gasoline engines, meaning they burn less fuel to travel the same distance, resulting in lower CO₂ emissions per kilometer. However, diesel fuel itself contains more carbon per liter, which slightly offsets its efficiency advantage.

- Diesel Engines: Emit 10-20% less CO₂ than gasoline engines due to higher fuel efficiency.

- Gasoline Engines: Emit more CO₂ per kilometer since they consume more fuel.

While diesel engines contribute less to global warming in terms of CO₂ emissions, they create more local air pollution due to NOx and particulate matter.

Particulate Matter (PM) and NOx Emissions

Diesel engines generate higher levels of nitrogen oxides (NOx) and particulate matter (PM) compared to gasoline engines. NOx emissions contribute to smog, acid rain, and respiratory problems, while PM consists of fine soot particles that pose serious health risks when inhaled.

- Diesel Engines: Produce significantly more NOx and PM due to high-temperature combustion and the absence of a controlled air-fuel mixture. Older diesel vehicles were major contributors to urban air pollution, but modern diesel engines incorporate advanced emission controls to limit these pollutants.

- Gasoline Engines: Emit lower levels of NOx and PM because of lower combustion temperatures and better air-fuel mixing. Direct-injection gasoline engines, however, have been found to emit more fine particulates compared to traditional port fuel injection systems.

Emission Control Technologies in Modern Engines

Both diesel and gasoline engines use advanced emission control systems to reduce harmful pollutants and comply with strict environmental regulations.

Gasoline Engines:

- Diesel Particulate Filters (DPF) – Captures and burns off fine soot particles to reduce PM emissions.

- Selective Catalytic Reduction (SCR) – Uses AdBlue (urea solution) to convert NOx into harmless nitrogen and water vapor.

- Exhaust Gas Recirculation (EGR) – Recirculates a portion of exhaust gases back into the engine to lower combustion temperatures and reduce NOx formation.

Gasoline Engines:

- Three-Way Catalytic Converters (TWC) – Converts NOx, CO, and unburned hydrocarbons into less harmful gases.

- trong data-start=”3238″ data-end=”3276″>Gasoline Particulate Filters (GPF) – Similar to DPF, but used in direct-injection gasoline engines to reduce fine particulates.

- EGR Systems – Also used in some gasoline engines to lower NOx emissions.

How do service intervals differ?

Service intervals vary between diesel and gasoline engines due to differences in oil contamination, engine load, and operating conditions. Diesel engines typically require less frequent oil changes but demand stricter maintenance for components like fuel filters and emission systems.

Oil Change Intervals

- Diesel Engines – Require oil changes every 10,000 to 25,000 km, depending on the engine type and oil quality. Diesel oil contains more detergents and dispersants to handle soot and combustion byproducts. However, heavy-duty applications may require more frequent changes due to higher loads and extreme conditions.

- Gasoline Engines – Typically need oil changes every 5,000 to 15,000 km, as gasoline burns cleaner than diesel and produces fewer contaminants. Modern synthetic oils extend service intervals, but gasoline engines still require more frequent oil changes than diesel engines.

Fuel and Air Filter Maintenance

- Diesel Engines – Require more frequent fuel filter changes, often every 15,000 to 30,000 km, since diesel fuel contains more impurities and water content. Diesel air filters also require regular checks due to higher soot levels.

- Gasoline Engines – Fuel filters generally last longer and may not need replacement for 50,000 km or more. Air filters need periodic inspection, but gasoline engines produce less soot, reducing clogging.

Emission System Maintenance

- Diesel Engines – Require Diesel Particulate Filter (DPF) regeneration and maintenance to prevent clogging. Selective Catalytic Reduction (SCR) systems also need AdBlue refills.

- Gasoline Engines – Need periodic catalytic converter inspections, but emission control components generally require less frequent servicing than diesel systems.