Whether you just heard the term engine oil weight and want to know more, or want to understand the difference between 10W30 and 10W20 for your car engine, you are in the right place.

What are Engine Oil Weights and How are They Determined?

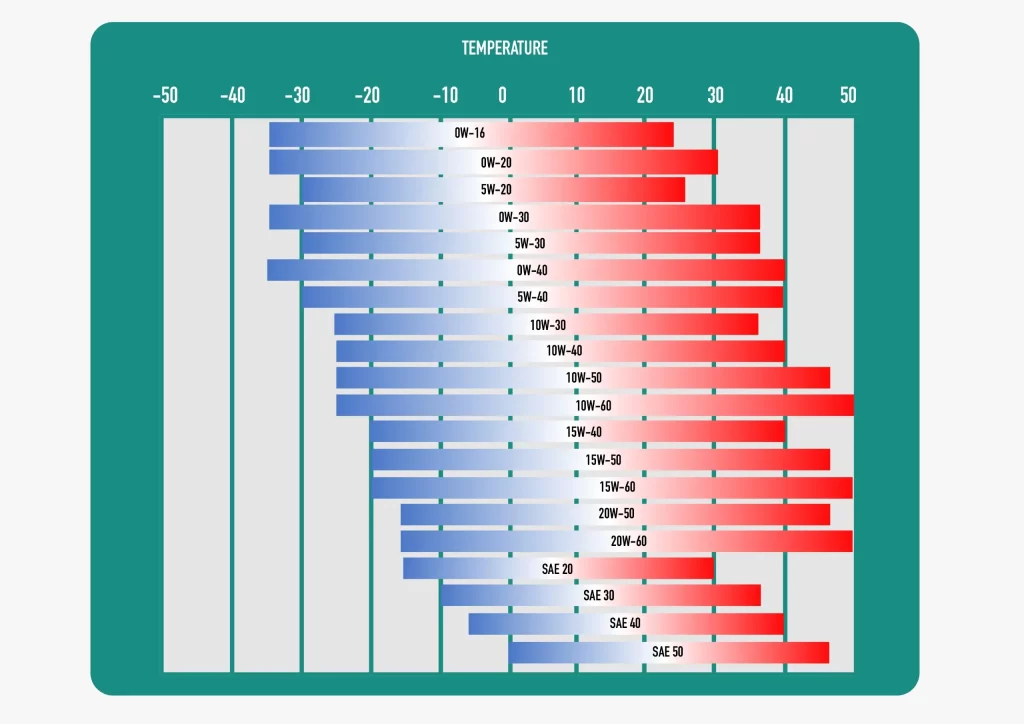

Oil weights represent an oil’s viscosity, or its resistance to flow, under different temperatures. The Society of Automotive Engineers (SAE) classifies motor oils using a numerical system that indicates how the oil behaves in cold and hot conditions.

Manufacturers determine oil weights through standardized tests that measure how the oil flows at different temperatures. The lower the number before the “W” (winter rating), the better the oil performs in cold starts. The second number represents the oil’s viscosity at operating temperature, affecting lubrication and engine protection.

What Do the Numbers in Oil Weights Mean?

The numbers in an oil weight, such as 10W30, indicate its multi-grade viscosity rating:

- “10W” (Winter Rating) – The oil remains fluid in cold temperatures, allowing smooth engine startup. Lower numbers, like 5W, perform better in extreme cold.

- “30” (Operating Temperature Rating) – The oil maintains a stable viscosity when the engine reaches its normal running temperature. Higher numbers, like 40 or 50, provide thicker protection for high-performance or heavy-duty engines.

10W30 Engine oil has Different viscosity in different temperatures has Different viscosity in different temperatures. Typical (Approximate) Kinematic Viscosities for 10W‑30 are usually like the following:

At 100 °C (212 °F):

- SAE Spec Range: 9.3–12.5 cSt

- Typical Product Data: Around 10–12 cSt

At 40 °C (104 °F):

- Usually in the range of 60–80 cSt (typical data sheet values; can be a bit higher or lower depending on the formula)

(Valus change for different products and we presented average number for educational purposes only).

How Does Viscosity Affect Engine Performance?

Viscosity can literally translate into the resistance of flow! Based on such definition it is safe to say higher viscosity means thicker oil that takes longer to flow to engine components. On the opposite side, lower viscosity indicates smoother flow.

Based on what we said it is logical to switch to lower viscosity right? NOT ALWAYS

Although it is great to have smoother flow and, reducing viscosity excessively jeopardizes lubrication. Oil needs to be thin enough to flow fast and thick enough to create a protective layer between moving parts keeping a constant layer between moving parts.

We can say oil viscosity impacts several critical aspects of engine performance:

- Cold Start Protection– Lower viscosity oils, like 5W-30 oil, flow easily in cold conditions, reducing startup wear.

- High-Temperature Stability– Higher viscosity oils, like 10W40, resist thinning at high temperatures, ensuring proper lubrication under heavy loads.

- Fuel Efficiency– Thinner oils reduce friction, improving fuel economy, while thicker oils provide extra protection for high-performance engines.

- Wear Protection– The right oil prevents metal-to-metal contact, reducing wear on engine components over time.

Which Engine Oil Weights Are Recommended for Different Engine Types?

Different engines require specific oil viscosities to function optimally:

- Passenger Cars & Light Trucks – Most modern vehicles use 5W30 or 10W-30 for balanced protection and efficiency.

- High-Performance Vehicles – Sports cars and performance engines benefit from 0W40 or 5W50 for extreme temperature stability.

- Heavy-Duty & Diesel Engines – Trucks and machinery often require 15W40 or 20W50 for enhanced wear protection under heavy loads.

- Cold Climate Vehicles – Cars in freezing temperatures perform better with 0W20 or 5W30 to prevent thickening in cold starts.

(Disclaimer) Please check your vehicles manual and engine’s cap before changing engine oil.

How to Choose the Correct Engine Oil for Your Vehicle?

The correct engine oil for your car is the one specified by your car manufacturer (you can find the correct weight in the manual or on the engine cap under the hood). When the manual is not available, you should select engine oil based on various factors, including viscosity, climate and driving conditions.

What Factors Should You Consider When Selecting Oil Type?

Choosing the right engine oil involves evaluating several key aspects:

- Viscosity Rating– Oils like 10W30 or 5W30 provide different levels of flow and protection under various temperatures.

- Driving Conditions– Vehicles exposed to heavy loads, stop-and-go traffic, or extreme temperatures may need a different oil grade than those used for highway driving.

- Engine Age and Type– Older engines may require thicker oils to compensate for wear, while modern engines perform best with low-viscosity synthetic oils.

- Oil Additives– Some oils contain detergents, anti-wear agents, or friction modifiers to enhance protection and efficiency.

Considering these factors helps in selecting an oil that maintains optimal lubrication and performance in all conditions.

What Does the Manufacturer Recommend for Your Car?

Manufacturers specify the ideal oil viscosity and type for each engine. Checking the owner’s manual provides:

- The recommended SAE viscosity grade (e.g., 5W30, 10W40)

- Whether the engine requires synthetic, semi-synthetic, or conventional oil

- Approved API (American Petroleum Institute) and ACEA (European Automobile Manufacturers Association) standards

Using an oil that meets the manufacturer’s specifications prevents engine wear, overheating, and reduced fuel efficiency. Vehicles with turbocharged or high-performance engines often require synthetic oils for better protection under extreme conditions.

How Can Oil Weight Affect Fuel Economy?

The viscosity of engine oil plays a direct role in fuel efficiency:

- Lighter Oils (e.g., 0W20, 5W30)– Reduce internal friction, allowing the engine to run more smoothly and consume less fuel.

- Thicker Oils (e.g., 10W40, 20W50)– Provide better protection in high-performance or older engines but may slightly increase fuel consumption due to added resistance.

- Multi-Grade Oils– Balance cold start protection and high-temperature performance, optimizing both fuel efficiency and engine longevity.

In Conclusion

Selecting an engine oil for ultimate engine protection with the right balance of viscosity helps improve fuel economy while maintaining engine durability and performance.