Torque measures rotational force that gets vehicles moving from standstill, whereas horsepower represents the rate of work over time that maintains speed. Think of torque as the initial push and horsepower as sustained power at higher speeds. Mathematically, horsepower equals torque multiplied by RPM divided by 5,252. Different vehicles prioritize these forces based on purpose—trucks need torque for towing, sports cars need horsepower for speed. Understanding both reveals why certain vehicles perform the way they do.

The Basic Physics Behind Horsepower and Torque

Why do cars sport two different power measurements? It’s because they represent distinct aspects of engine performance.

Torque measures the rotational force produced by an engine—the twisting effect that moves your vehicle from a standstill. Measured in pound-feet or Newton-meters, it’s what you feel pushing you back in your seat during acceleration.

Torque: the invisible hand that presses you into your seat when you hit the gas pedal. Horsepower, nonetheless, calculates how quickly work gets done, derived from the formula:

Horsepower = (Torque × RPM) ÷ 5252.

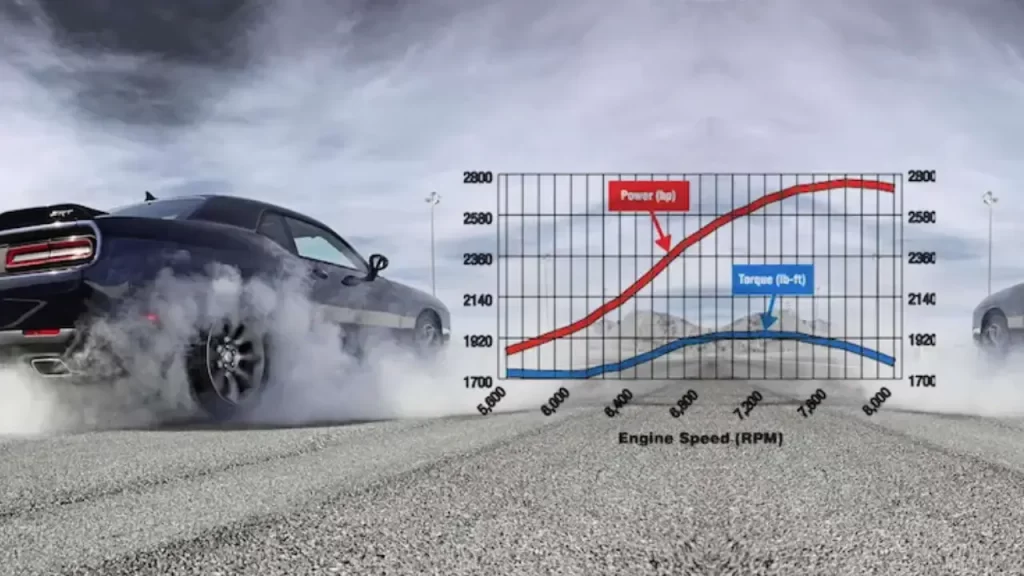

This measurement reveals the engine’s sustained power output at speed. The torque curve shows how force varies across different RPM ranges, whereas horsepower peaks at higher revolutions.

In the horsepower versus torque debate, both matter: torque launches you forward, whereas horsepower keeps you moving fast. Additionally, just as ISO hydraulic oil protects complex hydraulic systems by ensuring outstanding performance and protection under extreme conditions, both torque and horsepower are essential for a vehicle’s overall efficiency and endurance.

How Horsepower Affects Vehicle Performance

Horsepower directly influences a vehicle’s top speed capabilities, with higher ratings enabling greater maximum velocities as demonstrated by performance vehicles like the 717 hp Dodge Challenger Hellcat. This raw power output determines how effectively a vehicle can maintain high speeds and overcome air resistance at velocity.

Making horsepower vital for highway performance and racing applications. The relationship between a vehicle’s weight and available horsepower (weight-to-power ratio) fundamentally dictates real-world acceleration response and speed potential across driving conditions. In high-performance vehicles, DOT 4 brake fluid ensures superior braking power and control, complementing the engine’s output effectively.

Speed vs. Acceleration Dynamics

When discussing vehicle performance, distinguishing between acceleration and top speed capabilities reveals the critical role of horsepower. While initial acceleration depends heavily on torque, maximum power determines how quickly a vehicle can continue gaining speed once in motion.

A vehicle’s engine generates increasing horsepower as engine RPM rises, enabling sustained acceleration at higher speeds where torque alone becomes insufficient.

This explains why high-horsepower vehicles excel in highway passing and racing scenarios rather than just off-the-line starts. The relationship between power and acceleration becomes particularly evident when comparing vehicles with similar weight but different horsepower ratings.

Acceleration dynamics confirm that horsepower ultimately governs top speed potential, as it represents the engine’s ability to overcome air resistance at velocity.

For peak performance, engineers balance horsepower and torque across the entire engine speed range.

Top-End Performance Potential

The upper limits of a vehicle’s performance capabilities directly connect to its horsepower rating. While torque determines initial acceleration, horsepower becomes the dominant factor in achieving impressive maximum velocities. Performance vehicles like the Challenger Hellcat demonstrate how 717 hp translates to speeds exceeding 200 mph, showcasing the relationship between engine power and top-end speed.

| Vehicle Model | Horsepower | Peak RPM | Top Speed |

|---|---|---|---|

| Dodge Hellcat | 717 hp | 6000 rpm | 200+ mph |

| Camaro ZL1 | 650 hp | 6600 rpm | 190 mph |

| Mustang GT | 460 hp | 7000 rpm | 155 mph |

| Civic Type R | 306 hp | 6500 rpm | 169 mph |

>Horsepower ratings reveal a vehicle’s performance potential at high engine RPM, where sustained power delivery becomes essential. Unlike torque’s role in initial acceleration, high-speed performance depends on the engine’s ability to maintain power output at elevated speeds.

Weight-to-Power Considerations

A vehicle’s performance capabilities extend beyond raw power numbers, as the critical relationship between weight and horsepower finally determines real-world performance outcomes. This fundamental principle is captured in the power-to-weight ratio—a key metric for evaluating vehicle performance potential.

When an engine produces high horsepower in a lightweight chassis, vehicles can accelerate quickly and maintain higher speeds efficiently. Performance vehicles capitalize on this relationship by maximizing horsepower and minimizing weight.

Unlike heavier vehicles where both torque and horsepower are needed for towing, lightweight sports cars prioritize power-to-weight advantages.

Weight-to-power considerations explain why a 300-horsepower sports car might outperform a 400-horsepower SUV on a racetrack. For enthusiasts seeking ultimate performance, the balance between power and torque must be optimized relative to the vehicle’s weight class.

Why Torque Matters for Acceleration and Towing

Why does torque receive so much attention when discussing vehicle capabilities? Torque represents the rotational force that delivers the vital initial push needed to set a vehicle in motion. With high torque available at low RPM, vehicles can accelerate more responsively from a standstill and handle heavy loads with confidence. Additionally, the superior lubrication and protection provided by high-quality engine oils can enhance overall vehicle performance.

| Torque Benefit | Real-World Impact |

|---|---|

| Strong initial acceleration | Quicker off-the-line performance |

| Greater towing capacity | Ability to pull 12,200+ lbs trailers |

| Better low-end power | Less strain when climbing hills |

| Improved off-road capability | Freedom to conquer difficult terrain |

| Enhanced everyday drivability | Responsive performance in traffic |

>Peak torque output directly influences a vehicle’s towing capabilities, making torque figures essential for those seeking the liberation of hauling boats, trailers, or equipment without compromise.

The Mathematical Relationship Between Power and Torque

The mathematical relationship between horsepower and torque is expressed through the formula HP = (Torque × RPM) ÷ 5,252 for pound-feet measurements. This equation reveals that horsepower is fundamentally torque multiplied by rotational speed, then scaled by a constant factor determined by the units used.

Performance numbers demonstrate that even with constant torque, increasing engine speed proportionally increases power output, explaining why high-revving engines can achieve impressive horsepower figures in spite of modest torque ratings.

How Equations Work

Understanding the mathematical relationship between horsepower and torque requires exploring their fundamental equation that connects these two essential measurements. The horsepower equation expresses this quantitative relationship as HP = (T × RPM) / 5,252 for pound-feet, or HP = (T × RPM) / 7,127 for newton-meters.

This formula reveals how engine power calculation depends on both rotational force and speed. At constant torque, increasing RPM creates proportional gains in horsepower.

The horizontal power curve demonstrates why peak torque vs peak horsepower typically occur at different engine speeds. Although torque measures the twisting force, horsepower represents how quickly that force can be delivered.

The torque formula explains why two engines with identical torque but different RPM characteristics will produce vastly different power outputs—highlighting why units of measurement and mathematical understanding are essential for proper vehicle performance evaluation.

Calculating Performance Numbers

Calculating performance numbers reveals the precise mathematical relationship that ties horsepower and torque together as interrelated yet distinct measurements.

Engineers and enthusiasts use the formula Horsepower = (Torque × RPM) ÷ 5252 to understand how these forces interact within an engine’s power delivery.

- Peak power occurs at the specific RPM where the torque-RPM product reaches its maximum value when divided by the constant 5252.

- Engines with identical torque numbers can produce vastly different horsepower figures depending on their operational RPM range.

- The horsepower vs torque relationship explains why high-revving engines can achieve substantial power despite moderate torque.

- Performance calculations allow engineers to optimize engines for specific applications by determining where in the RPM band to maximize either torque or horsepower.

Gas vs. Electric: Different Power Delivery Systems

When comparing gas engines to electric motors, fundamental differences in power delivery systems particularly impact vehicle performance.

Gas engines build torque gradually, requiring high RPM to reach their power potential, with peak torque typically arriving at mid-range engine speeds. This characteristic necessitates gear changes to maintain ideal performance zones.

Electric motors, conversely, deliver instant torque from zero RPM, creating remarkable linear acceleration without waiting for engine speeds to climb. Their power delivery system remains consistently available, eliminating the need for traditional transmission shifting.

The torque curve in electric vehicles is practically flat and reaches maximum output immediately, unlike the variable curve of combustion engines. This instant power translates to quicker off-the-line response, despite what traditional horsepower numbers might suggest on specification sheets. Additionally, the use of premium diesel engine oil can greatly enhance the longevity and lubrication efficiency of gas engines, improving their performance.

Practical Applications: Choosing the Right Power Profile

Selecting the appropriate power profile for a vehicle depends critically on its intended purpose and operating conditions.

The distinction between horsepower vs torque makes all the difference in how a car accelerates and performs in various situations. Higher torque at low RPMs separates an ordinary engine from a good one when specific tasks are required.

- Towing vehicles prioritize torque makes – diesel trucks with 460 lb-ft torque can haul 12,200 lbs effortlessly.

- Sports cars emphasize the power produced by the engine at high RPMs – Hellcats with 717 hp achieve impressive top speeds.

- Off-road vehicles require substantial torque at low ranges for conquering steep terrain.

- Electric vehicles like Tesla’s Model S Plaid demonstrate what power an engine can produce instantly, delivering both acceleration and efficiency. Additionally, proper maintenance using Motorcycle Fork Oil can significantly improve performance and handling in various vehicles.

High Torque vs. High Horsepower: Which Matters Most?

The age-old debate between high torque and high horsepower continues to influence vehicle purchasing decisions across various segments. The answer ultimately depends on intended use: high torque provides immediate pulling power at lower RPMs, making it crucial for towing heavy loads or conquering off-road terrain.

The amount of torque available, especially in the lower power band, determines how effectively a vehicle can accelerate from standstill.

Conversely, high horsepower measures a vehicle’s ability to maintain speed, becoming most relevant at higher RPM ranges. Performance enthusiasts often seek vehicles with balanced compression and torque capabilities that deliver across the entire power band.

Modern engineering increasingly focuses on achieving both peak torque at low RPM and substantial horsepower at higher RPM, creating versatile vehicles that excel in various driving conditions. Additionally, the use of premium motor oil can enhance engine performance, ensuring optimal functionality across different RPM ranges.

Conclusion

Understanding the distinction between horsepower and torque enables better vehicle selection based on specific needs. Whereas torque provides the initial force for acceleration and towing capacity, horsepower determines top-end speed and sustained performance. Their mathematical relationship reveals their complementary nature across different engine types. In the end, the ideal balance depends on intended use—whether hauling heavy loads or achieving high-speed performance.

Remember that proper maintenance, including regular oil changes with high-quality lubricants, is essential for maximizing engine lifespan, reducing friction, and minimizing wear. Explore Armor Lubricants’ range of engine oil manufactured in UAE designed to protect your engine.